Well treatment

What Is A Water Well?

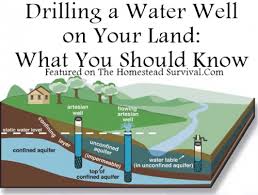

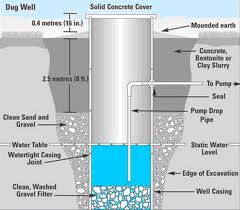

A strict definition of a water well is an artificial pit, hole, or tunnel, drilled, dug, driven, or jetted into the ground to a depth that penetrates a water-yielding formation to allow water to flow or to be pumped to the surface. More simply defined, a water well is a man-made hole in the ground through which ground water may flow or be pumped to the surface. Whether the ground water is shallow or deep, we must have a way to link the ground water to the surface where it can be used. This is done by constructing a water well .

There are several components that make up the basics of a water well . First, a source of water is needed. This is generally supplied by an aquifer . Second, a conduit for routing the water to the surface, called casing, is needed, and thirdly, some sort of pump is necessary to deliver the water. An analogy of these components is drinking soda through a straw. The soda in the glass is equivalent to ground water in an aquifer , the straw is the casing , and the human body acts as the pump.

How Are Water Wells Constructed?

A variety of methods are used to construct water wells, depending on the geologic conditions and the intended use of the well. Two general types of well construction are used in South Dakota. One type consists of extending casing down the borehole through the upper loose sediment or rocks, but leaving the bottom portion of the borehole uncased. This type of well construction is usually used in hard, fractured rock. The other type consists of extending casing down the borehole through sediment or rock and placing a well screen in the aquifer . This type of well construction is commonly used in unconsolidated sediment, such as sand and gravel (Driscoll, 1986).

Well construction has five or six separate steps. These include drilling, installing the casing , installing the well screen , installing the filter pack, grouting , well development , and installing a permanent pump (Driscoll, 1986). Two or more of these steps may be done simultaneously. For example, installing the casing and screen may be done in one step. For some wells, a pump may not be needed because the water will flow to the surface. These are called flowing wells. Listed below is a typical well construction procedure.

1. Drilling Operations

Drilling methods vary widely and range from digging by hand to the use of very technical and expensive drilling rigs. All drilling methods accomplish the same task, creating a borehole . Most drilling operations are completed by the use of some sort of drilling rig. The rig is set up over the prospective well location and drilling continues until the desired depth has been reached.

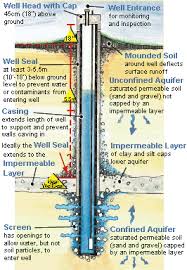

2. Installing the Casing and Screen

Once the desired depth of the borehole has been reached, the drill crew can then install the casing and screen. Casing can be made of different materials, such as steel or plastic, and comes in various diameters and lengths. Well screens are also available in various material types, diameters, and lengths, and have slots or holes cut in them. The slots or holes are sized to allow water to flow into the well and keep unwanted materials, such as sand, out. Well screens are usually attached to the first piece of casing to be put down the borehole and successive pieces of casing are then added until the entire length of the borehole has been screened or cased.

3. Installing an Artificial Filter Pack

For some well designs, it is necessary for an artificial filter pack to be placed around the screen. This operation takes place before grouting or sealing the well. The filter pack consists of graded sand or gravel, which is placed around the well screen . The filter pack removes or filters unwanted fine particles from the formation that would otherwise find a way into the well. These fine particles could cause the well water to appear cloudy.

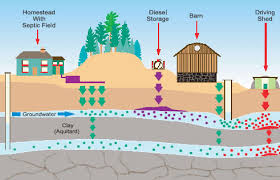

4. Grouting the Well

Grouting a well involves filling the space between the casing and borehole wall with a slurry of cement or clay. This is done to seal the area between the casing and borehole wall to prevent downward leakage of contaminants from the surface, or to prevent intermixing of ground water between water-bearing zones encountered while drilling.

Grouting can be accomplished by several methods, but all involve the mixing and placement of either a bentonite clay slurry or a neat cement slurry in the annular space between the borehole and the casing . The most common type of grout used in the water well industry today is neat cement . The section of the borehole to be grouted varies according to geologic conditions, the type of water well being constructed, and water well codes . Once the grouting process is completed, the well is ready to be developed for its intended use.

5. Developing the Well

Well development is a procedure intended to maximize the well yield . During the drilling operation, damage to the formation or aquifer occurs. This happens when the drill bit cuts through the rock or sediment leaving behind small pieces of rock or sediment that may plug the well screen and reduce the yield of the well. Also, during the drilling operation, different fluids may be introduced to the borehole to remove cuttings and to prevent it from collapsing. There are two main reasons for well development : (1) repair damage done to the formation during drilling, and to remove unwanted fluids, so that the natural properties of the aquifer are restored; and (2) change the physical properties (porosity and permeability ) of the aquifer near the borehole so that water will flow more freely into the well (Driscoll, 1986).

A variety of techniques are used to develop wells. Some are as simple as bailing the well, and others may involve a complex operation of high capacity pumping and jetting . The screened area of the well, or the uncased unscreened portion of a borehole , is where the development takes place because this is the area where water will enter the well. All of the techniques have their advantages and achieve the same goal. This is to increase the amount of water that can be delivered to the surface for use. With development complete, a permanent pump can be installed, if necessary, and the well can be put to use.

What Are Water Wells Used For?

Water from wells in South Dakota is used for many purposes, including irrigation, human and livestock consumption, and for commercial, mining, industrial, and geothermal applications. What is discussed in this fact sheet is only a portion of what is a highly technical and complex industry in South Dakota and across the world.

Glossary

Annular space - the space between the casing or screen in a well and the wall of the borehole.

Aquifer - a body of rock or sediment that is sufficiently permeable to conduct ground water and to yield economically significant quantities of water to wells and springs.

Artificial filter pack - artificially graded material surrounding the well screen in a water well.

Bailing - the repeated lowering, filling, raising, and emptying of a bailer to remove fluid from a well. A bailer is a cylindrical tube fitted with a valve at the bottom.

Bentonite - a clay material used in the water well industry as a drilling mud and as a well sealing material to slow or stop water movement.

Borehole - a circular hole made by boring or drilling to access a particular geologic unit.

Casing - a pipe lowered into a bore hole during or after drilling and grouted into place.

Formation - a body of rock identified by certain geologic characteristics; term applied by drillers to a rock or sediment that can be described by certain drilling characteristics.

Geologic - pertaining to or related to geology, which is the study of the planet Earth.

Ground water - all subsurface water.

Grouting - the process of placing a cement or clay slurry to fill or seal fractures or spaces.

Jetting - the process of loosening and flushing cuttings or loosely consolidated materials from a borehole or well, by using a directed forceful stream (jet) of air or water.

Neat cement - a mixture of portland cement and water, in a certain proportion, used for grouting wells.

Permeability - the capacity of a rock or sediment to transmit a fluid.

Porosity - the ratio of the volume of void spaces in a rock or sediment to the total volume of the rock or sediment.

Water well - an artificial pit, hole, or tunnel, drilled, dug, driven, or jetted into the ground to a depth that penetrates a water-yielding formation to allow water to flow or to be pumped to the surface.

Water well codes - a set of regulations or standards to be followed and enforced for the construction of water wells.

Well development - the act of repairing damage to the formation caused by drilling procedures and increasing the porosity and permeability of the materials surrounding the intake portion of the well.

Well screen - a section of well casing which has been perforated or slotted to allow inflow of water and to keep unwanted materials from entering the well.

Well yield - the amount of water that can be withdrawn from a well per unit time.

Glossary terms are adapted from Bates, R.L., and Jackson, J.A., 1987, Glossary of Geology , American Geological Institute,

Alexandria, Virginia, and from Driscoll, F.G., 1986, Groundwater and Wells , St. Paul, Minnesota, Johnson Division,

second edition, 1,089 p.

References

Driscoll, F.G., 1986, Groundwater and Wells, St. Paul, Minnesota, Johnson Division, second edition, 1,089 p.

Selected Resources For Teachers

To learn more about the well construction standards of South Dakota the reader is referred to the portion of South Dakota

Codified Law, Chapter 74 02 04, Well Construction Standards of the State of South Dakota , revised July 1992.

For more information on hydrogeology a suggested text is, Applied Hydrogeology , by C.W. Fetter, Jr., 1980, published by

Charles E. Merrill Publishing Co.

Outreach (Resource Agency Personnel)

(See Natural Source Directory for phone numbers)

Department of Earth Sciences/Physics, University of South Dakota , Vermillion, SD 57069.

Division of Geological Survey, Department of Environment and Natural Resources ,Vermillion, SD 57069.

Division of Water Rights, Department of Environment and Natural Resources , Pierre, SD 57501.

Geology Department, South Dakota School of Mines and Technology , Rapid City, SD 57702.

Water Resources Research Institute, South Dakota State University , Brookings, SD 57007.

Written by:

Layne D. Schulz, Division of Geological Survey, Department of Environment and Natural Resources, Vermillion, SD 57069.

1995.

Reviewed by:

Derric L. Iles, Division of Geological Survey, Dept. Environment and Natural Resources, Vermillion, SD 57069.

Publication of the Water Well Construction fact sheet was funded by the South Dakota Department of Game, Fish and Parks,

Division of Wildlife, Pierre, SD.

English

English

Italiano

Italiano Español

Español